Technical Resources

LABORATORY

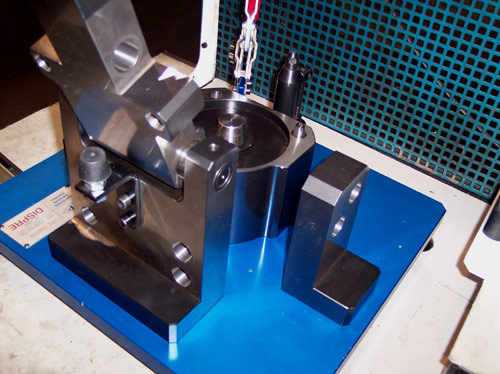

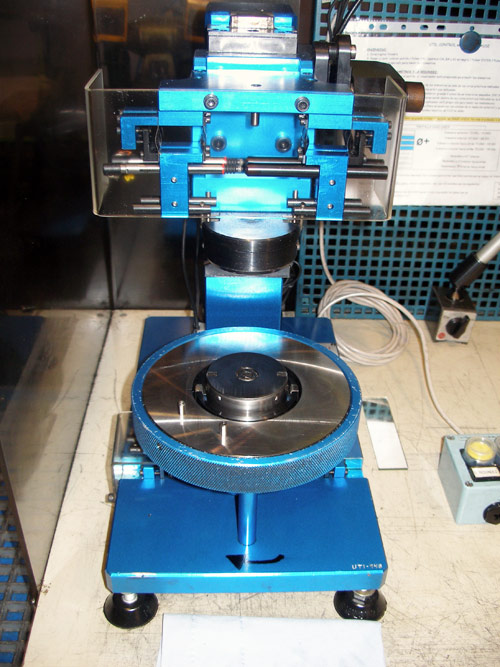

The Quality laboratory is located in the Manufacturing facility and is approximately 50 m2 in size. It has many different means of verification (gauges, patterns, smooth, screw and conical pads, bases, calipers, hundredth and thousandth comparators, gage markers, flexometers, micrometers, ...) which are systematically calibrated. The laboratory also has a profile projector, three-dimensional machine, and a surface roughness and hardness tester.

All MECALSA staff is aware of the importance of quality in their activity and are trained and accountable, carrying out checks of the manufacturing processes.

Maximum importance is given to the quality assurance of our clamping tools and verification tools.

VERIFICATION LIMITS

- CNC Lathe Machining: diameter and length tolerances of up to 0.010 mm under normal conditions.

- CNC Center Machining: positioning tolerances guaranteed up to 0.05 mm.

- Both limits can be reduced, of course, with greater scrutiny of the processes.

CALIBRATION LIMITS

Internal calibration is carried out under controlled conditions, verifying the control tools and using software for this purpose. Repeatability and Reproducibility studies (R & R) are conducted and the capacity of the processes is analyzed.

La calibración EXTERNA es realizada siempre por laboratorios acreditados.

External calibration is always performed by accredited laboratories.

TECHNICAL DEPARTMENT

- The Technical Department is located on a mezzanine floor, just above the laboratory.

- It is 25 m2 in size and has a extensive technical library.

- Meetings are held there for Advanced Quality Planning, the Management Committee for the review of systems, and Customer Engineering in order to resolve engineering issues related to machined parts.

- Preliminary sketches of the clamping tools are made there in collaboration with the tools' manufacturer.